Baptist Hospital

Jacksonville Beach, Florida

Revitalizing Chiller Plant to Ensure Optimal Performance and Energy Efficiency in Critical Care Settings.

Baptist Hospital’s chillers were not operating at optimal capacity. After loud and unstable conditions emerged and a surge condition was detected, ThermaServe was called in to correct the chiller plant problems and increase energy efficiency for this critical care facility.

Challenge

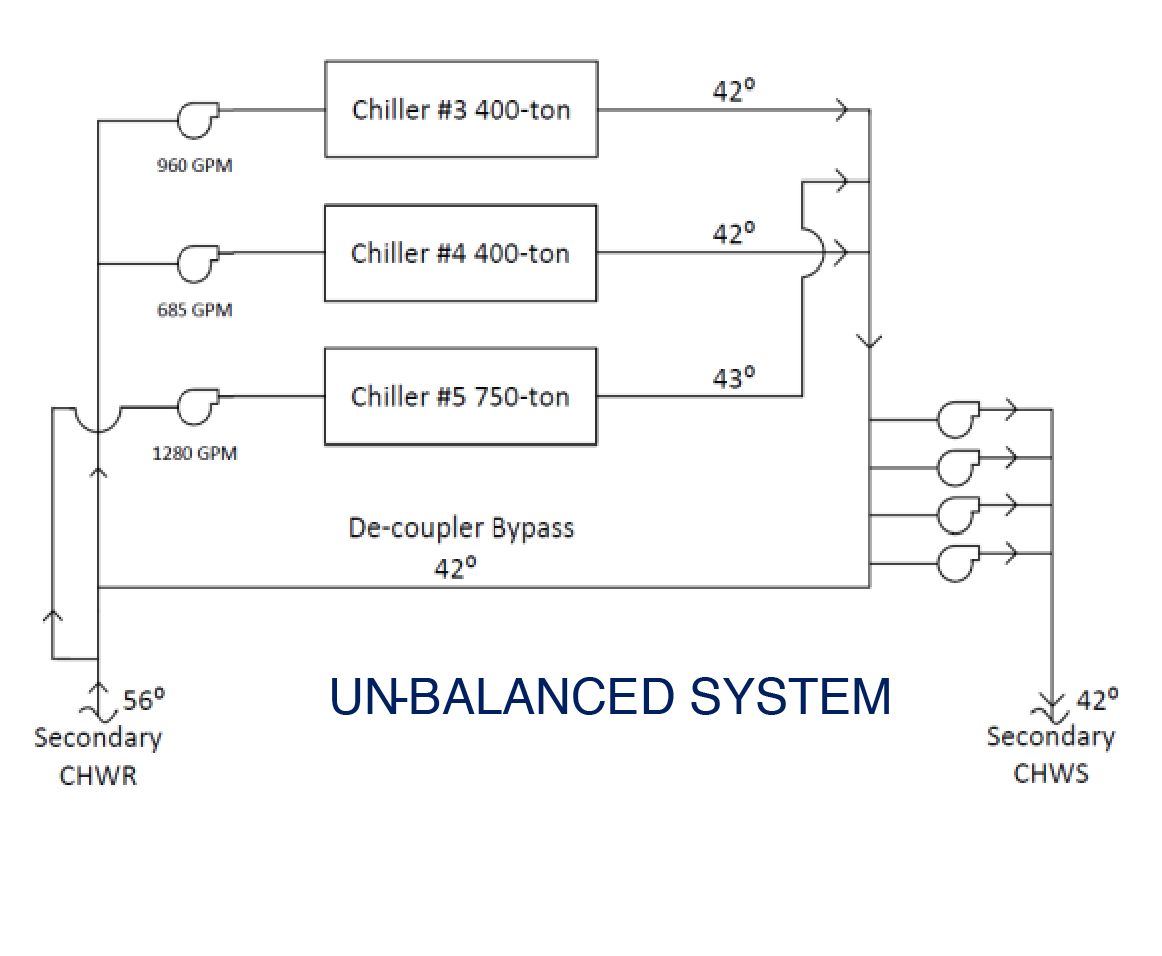

The hospital’s 400-ton constant speed centrifugal chiller #4 operated at considerably less design capacity than the 750-ton chiller #5 when these two operated together. The low load operating condition of the 400-ton chiller was causing loud and unstable conditions and a surge condition. Baptist Hospital wanted to correct the chiller plant problems and increase energy efficiency.

Analysis

When both centrifugal chillers were operating, the 750-ton chiller return temperature was the same as the return secondary water temperature, but at the same time, the return water temperature to the 400-ton chiller was at a lower mixed water temperature. This condition caused the 400-ton chiller to operate at a much lower percentage of design load than the 750-ton chiller. The York 400-ton constant speed centrifugal chiller runs inefficiently at low loads. If this chiller was variable speed, it would operate very efficiently at low loads.

Solution

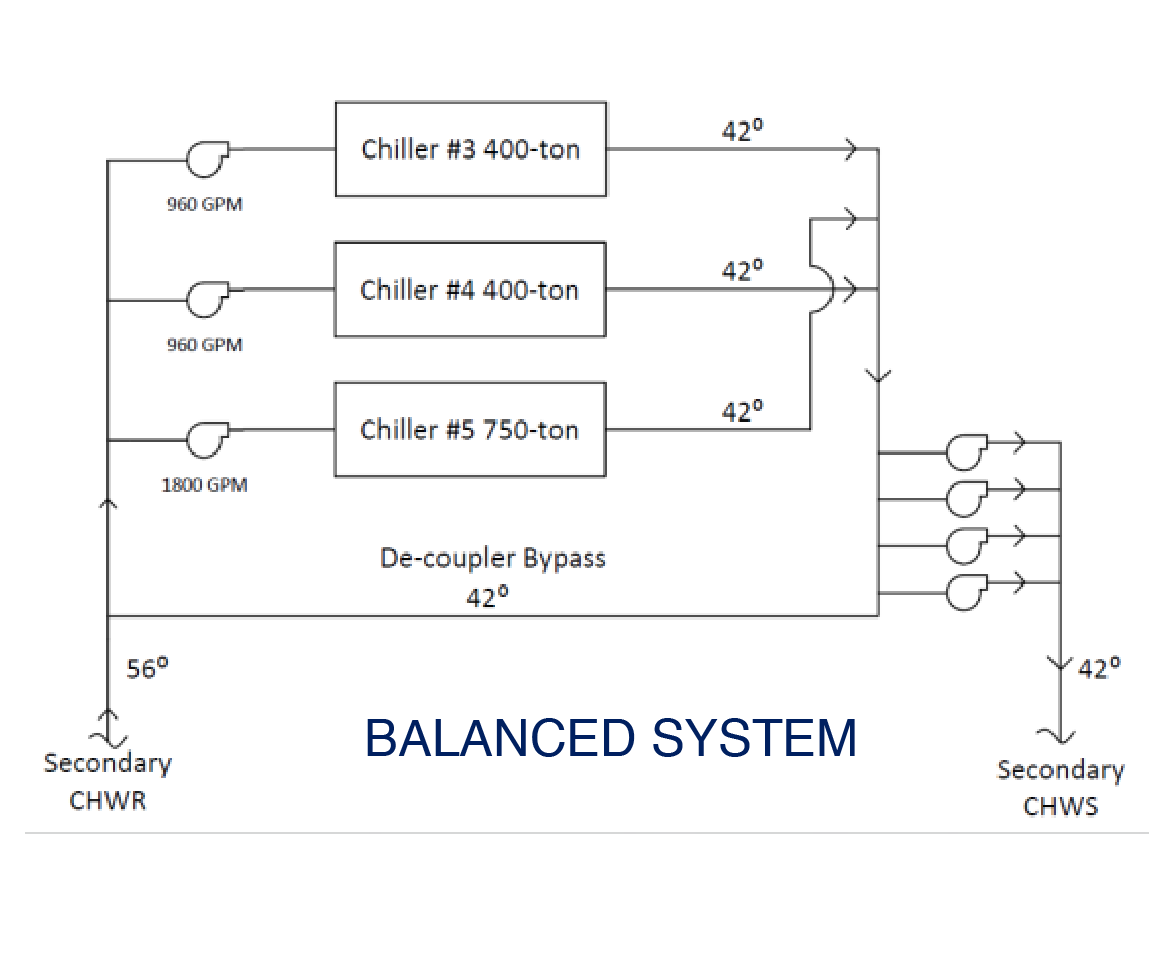

We relocated the 750-ton chiller chilled water return pipe connection from the secondary loop chilled water return to the primary loop chilled water return. We reconfigured the primary chilled water pumps to provide 2.4 gallons per minute per ton and replaced the solid-state starter for the 400-ton chiller with a variable speed drive. We supervised building automation personnel in reprogramming the chiller plant control system for optimal chiller staging and condenser water temperature control.

Results

The estimated energy savings from the project represent a 1.23-year payback, and the project cost was money well spent to extend the life of the 400-ton chiller and reduce the plant’s energy consumption. Baptist Hospital was extremely pleased with the results.

← Return to Projects